Feedstock from metallurgical waste

We will transform your metallurgical waste into EcolBriq®, a high-quality feedstock tailored to the needs of your plant. Our solution, protected by a European patent, enables you to recycle waste, including the types most difficult to process.

EcolBriq®

Full value replacement of your feedstock produced from waste and by-products.

by EcolBriq®

carbon footprint reduction

from EcolBriq®

content

Profit from waste

We cold process your waste to EcolBriq® briquettes to replace some of the metallic feedstock in your plant. We optimize the composition of EcolBriq® according to your requirements to improve your production processes and use of materials, and to reduce CO2 emissions. Our EcolBriq® is appropriate for all furnace types: from small cupola furnaces through blast furnaces, tandem furnaces and electric arc furnaces to converters.

Benefits

- Profit from high-quality feedstock

- Reduce costs for primary feedstock

- Reduce costs for emission allowances

- Totally avoid landfill costs

in feedstock production

and utility models

are already successfully using our technology

Double your value

(million EUR)

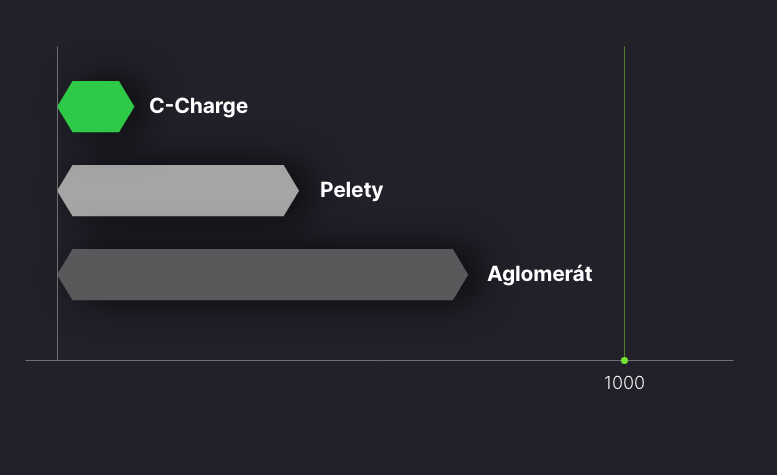

Feedstock

Circular feedstock

Hot briquetted iron

Reduce your carbon footprint